What is a Bench Vice and What is it Used for in the Workshop?

Like an extra set of hands, bench vices attach to your workbench to help you to hold wood, metal, and other materials securely in place while you work, freeing up both of your hands to perform the action you need to complete – for example, sawing, filing, or drilling.

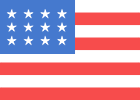

Different types of vices support different functions and are designed to be used with specific materials. Being able to tell each vice type apart, and its main uses, is the key to working with vices safely, as well as ensuring the quality of your workmanship.

Bench Vice Parts and Functions

Bench vices are one of the most popular types of vices used by professional tradespeople, craft hobbyists, and home DIYers.

Common bench vice parts and functions include:

Base

the part that affixes to the workbench.

Adjustable jaw base

this moves backwards and forwards, as necessary, to grip the material you’re working on.

Static jaw

this is a fixed jaw that doesn’t move, but which faces the adjustable jaw.

Jaw plates

interchangeable faces of the jaws, typically manufactured from hardened steel.

Spindle or threaded screw

this turns to provide motion to the vice’s adjustable jaw.

Handle

the handle is connected to the spindle. It is hand-operated and turns the screw as you turn the handle, thereby making the jaw of the vice open or close (depending on the direction you turn the handle).

Bench Vice Types and Uses

Different types of bench vice are designed to support different applications. That’s why you’ll find a wide variety of vices available on our website, ranging from a metalworking vice and a woodworking bench vice, right the way through to hand vices and a heavy duty bench vice.

To guide you in your vice selection, we’ve broken down the different vice types and their main uses:

Bench Vices with Fixed Base

A workshop bench vice with a fixed base is the most common of all vices.

Made from hardened steel or cast iron, they feature a fixed base that attaches to the workbench and components including a handle, spindle, an adjustable jaw, and a static jaw.

Bench Vices with 360°Swivel Base

Swivel based bench vices are almost identical to a fixed base vice, with the exception that their base allows for the vice to rotate from side to side.

This vice type is handy when you don’t have a lot of room around you.

Vacuum Vices

Vacuum vices are fitted with a suction pad that holds materials without the risk of marking them.

They are compatible with any material type, providing the workpiece has at least once flat and smooth surface.

Clamp-on Portable Table Vices

Portable clamp-on vices are equipped with fold-out legs and a clamping system that enables you to work between locations.

You may find these on job sites or for indoor work at client residences. The adjustable jaw in these devices is controlled with a foot pedal instead of the usual handle.

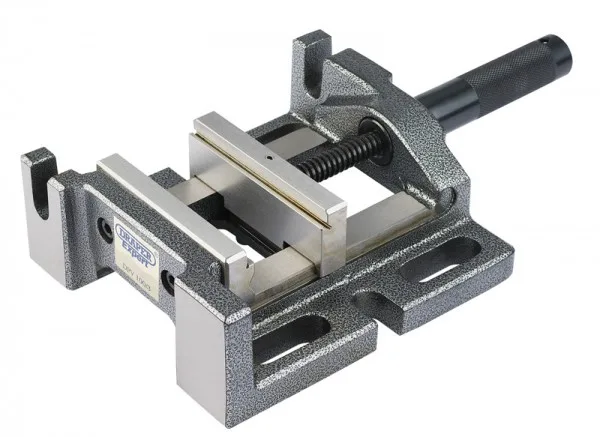

Drill Press Vices

Drill press vices are designed for use with pillar drills.

They feature a clamping system that stabilises the vice to your workbench and expandable jaws that hold your workpieces securely in place during drilling.

Metalworking Vices

A metal working vices sometimes referred to as a machinist’s vice or an engineer’s vice.

Designed for metalworking applications, metalworking vices feature replaceable jaws, that can be covered with a soft material to protect the component during use.

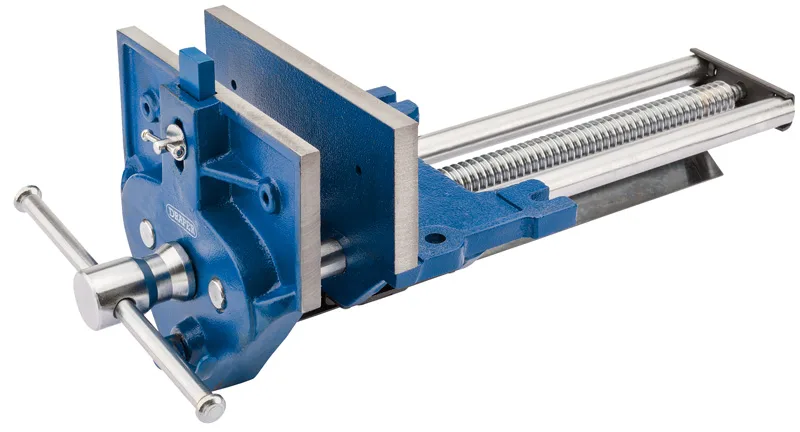

Woodworking Vices

A woodworking vice is designed to hold wood.

Contrary to other vice types, woodworking vices feature two in-built guide rods, which ensure that both the static and adjustable jaws always remain parallel.

Pipe Vices

Used primarily in the plumbing industry, pipe vices are designed to hold circular tubes or rods and are the perfect vice to choose when you need to cut threads into pipes.

In a pipe vice, the static jaw is shaped into an arch and the base allows it to be clamped to the end of a workbench. Some bench vices can be used as pipe vices, simply by screwing on a pair of interchangeable pipe gripping jaws.

Hand Vices

Hand vices are designed for smaller workpieces and more intricate applications. Used widely in jewellery assembly, hand vices – like locking pliers – allow you to grip small components of any shape, keeping your fingers clear while performing tasks such as polishing and sanding.

Many hand vice types come with head pins that enable you to clamp fiddly components more securely. Others feature a removable handle cover, giving you the option to insert the vice head into a bench vice.

Heavy-duty Vices

A heavy-duty bench vice is what is known as a forged vice. This means that the vice has been made from a solid chunk of metal, which has been heated and hammered into shape, as opposed to cast from molten metal poured into a mould.

Heavy-duty vices are generally more solid, durable, and stronger than their casted counterparts. They are the type of vice used by blacksmiths and can withstand heavier blows without compromising their integrity.

Factors to Consider Before Buying a Bench Vice for Your Workshop

Jaw opening

When using a vice, it’s important to ensure that the jaw opening aligns with your workpiece. Using the wrong size jaw can cause the material in your vice to slip, putting you at risk of injury, or even damaging your vice.

To determine the correct jaw size to use each time, measure the dimensions of your workpiece and refer to your manufacturer’s instructions for guidance.

Material

What you intend to put into your vice also has a bearing on the vice type you choose.

If you’re working with metals, you should opt for a metalworking vice. For wood, you want a woodworking vice, and for pipes or rods, you need a pipe vice.

Metalworking vices are also compatible with more fragile materials, providing the jaw faces are fitted with a soft covering. If you want to ensure the workpiece isn’t marked in any way, you should consider using a vacuum vice.

Mounting and base type

The position of your vice and the clearance you have around it to work is another factor you need to consider when choosing a vice to invest in.

Portable vices are great if you conduct most of your work on location, for example on a construction site. If you mainly work on a workbench, a fixed base or a swivel base vice is likely to better suit your needs.

While a fixed base will only allow you to work in one position, a swivel base vice can rotate, giving you more flexibility. This can be a helpful vice type to choose if your workspace is small or an irregular shape.

Bench Vice Spare Parts

Vices like any tool accessory can deteriorate over prolonged use and with natural wear.

The good news is it’s possible to pick-up spare parts to replace certain components of your bench vice, allowing you to responsibly extend its lifetime.

Bench vice spare parts typically include jaws, bases, and clamping screws. Just be sure to double check when you’re buying your vice that it’s compatible with interchangeable parts.

Workbench Vice Safety Tips

Although perfectly safe when operated correctly, vices can lead to injuries if not properly handled or maintained. Some tips for working safely with vices include:

- Always wear protective equipment such as goggles, safety glasses, and/or a shield.

- Ensure your vice is securely attached to its worksurface and stable before each use. Make sure that the workbench is strong enough to hold under sustained pressure.

- Never tighten the vice more than is needed. Similarly, do not attempt to force open the jaws any wider than their design permits.

- Inspect your vice for stress fractures and replace any affected parts immediately. Do not use the vice if a stress fracture or other crack has developed.

- Keep the moving parts of your vice well lubricated and clean.

Popular Bench Vices

Looking to expand your vice collection or add in a vice with workbench to your tool arsenal? Choose from our most popular bench vices or browse our full Red Box Tools vice selection.

Ready to get organised?

Find your perfect tool storage from our professional range

From tool bags and tool chests to tool boxes with wheels, tool belts, tool cases, and trade-specific tool storage, at Red Box Tools we offer high-quality solutions you can count on.

Or why not take your tool storage to the next level with our made-to-order tool box foam drawer inserts and custom shadow foaming?