Hammers are undoubtedly one of the most basic and easy-to-operate hand tools, especially when it comes to home DIY. They’re also one of the most versatile tools to work with, helping you to do everything from driving nails, to striking, straightening, and bending metals.

Identifying the different types of hammers and understanding the uses of hammers is key to choosing the correct tool for the task. If you’re new to working with hammers or unsure which hammer – or hammers – you need for a job, this guide to the types of hammers and their uses will explain all you need to know.

Types of Hammers

1. Sledgehammer

A Sledgehammer is a large and heavy hammer that you swing with force – in the same way that you’d handle an axe. They’re distinguishable by their long handle and flat-faced, double-sided, head.

Sledgehammers administer strong blows, and are great for tasks such as demolishing walls, driving-in stakes, or breaking-up masonry.

2. Claw Hammer

A claw hammer features a small, circular, flat face on one side and a narrow two-pronged opening on the other. They’re one of the most recognisable and common hammer types. In fact, most people will have a claw hammer at home.

The flat sided face is used for striking tasks, such as driving-in nails, while the claw-shaped side allows you to pull out nails. They’re an essential tool for carpenters, as well as anyone who regularly works with wood and nails.

3. Ball Peen Hammer

A ball peen or ball pein hammer is flat faced on one end and rounded on the other.

They’re a popular hammer type for metalwork applications, the flat end is used for tasks such as driving punches, setting rivets, and the rounded -pein end is for shaping metal.

4. Mallet

A mallet is a soft-faced hammer, perfect for non-marring applications.

Their head is typically manufactured from rubber and they’re ideal for landscaping tasks such as driving in stakes or setting paving stones. They’re perfect for gently nudging ceramic tiles or laminate flooring into place, ensuring a flawless finish.

5. Club Hammer

A club hammer has an evenly balanced, symmetrical head, with two flat-faces.

Their design makes them perfectly suited to heavy-duty and demolition tasks that don’t require something as forceful as a sledgehammer.

6. Cross Pein Hammer

A cross pein hammer is primarily a type of metalworking and blacksmithing tool.

It has a similar appearance to a club hammer, with the exception that one side of its head is tapered into an angular point.

7. Tack Hammer

A tack hammer is a lightweight hammer type that features a small square face for striking on one side and a narrow, elongated, opening on the other end.

They allow for pin-point accuracy when striking and their main applications include fine detail and upholstery work.

8. Dead-Blow Hammer

A dead-blow hammer is usually made from a polyurethane shell, which is filled with loose steel or sand.

They’re designed to reduce rebound and minimise damage and are commonly used to move or adjust an item without denting or marking it.

9. Specialty Hammers

Speciality hammer types include tethered hammers, which feature wire loops or eyebolts fixed to the handle and head for improved user ergonomics, and non-sparking hammers, which are essential when working in flammable environments.

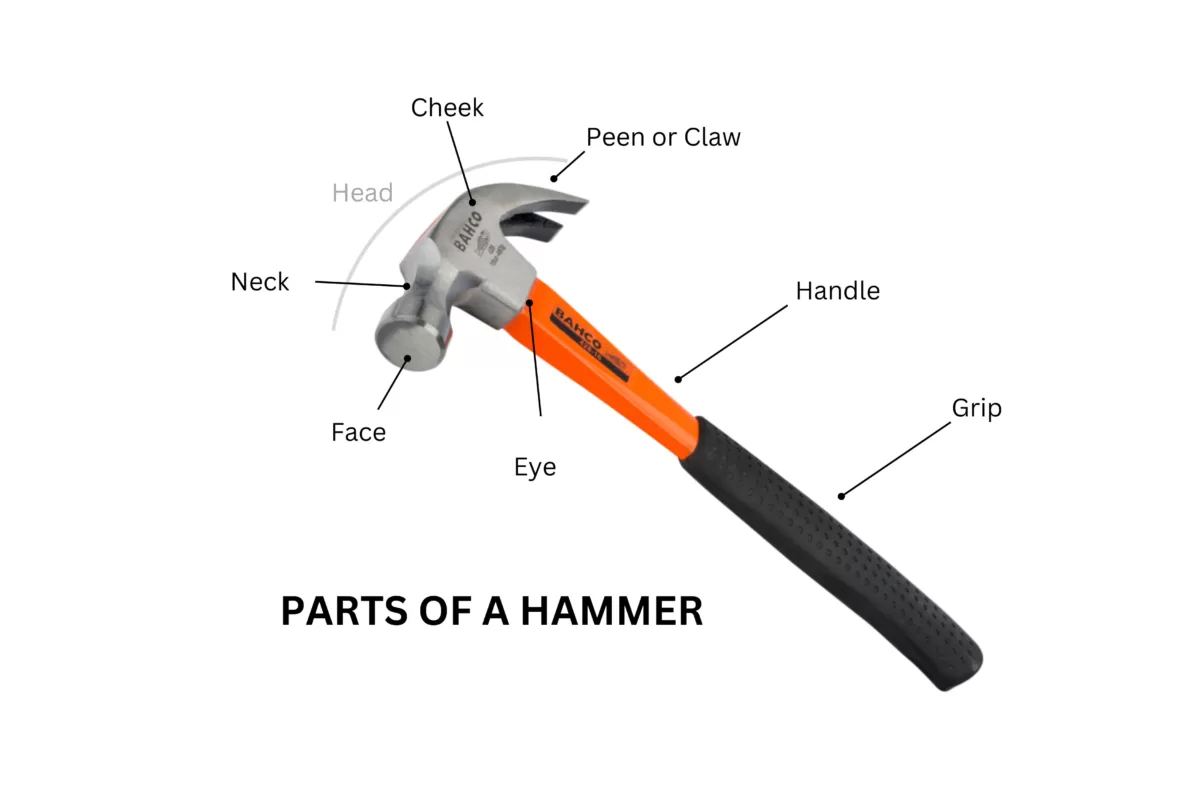

Parts of a Hammer

All hammers comprise of a handle and a head, but other features, such as the face, cheeks, and eye, can help you to easily identify one type of hammer from another – a crucial part of selecting the correct hammer for the job.

Here’s the key components of a hammer in more detail:

Handle

The handle is the part of the hammer you hold onto. Most hammers have a handle manufactured from wood, fibreglass, or steel. Hammer handles also vary in length, which can affect leverage and control when using a hammer.

Head

The head is everything that is affixed to the top of the hammer handle. It is the part that will make contact when you’re delivering the blow. Hammer heads are typically made from steel and metal alloys, although some hammer types, such as mallet hammers and dead-blow hammers, have heads made of soft materials, most commonly rubber or polyurethane.

Face

The hammer face is the striking side of the hammer. It can be flat or rounded, point-like or square, depending on the hammer type and its main uses. A hammer face can also have a smooth or a waffle textured surface.

Eye

The eye is the hole that connects the hammer head to the handle.

Cheeks

The cheeks on a hammer are the thin, metal, parts, positioned at either side of the hammer eye. They can also be used as a tool to drive-in if there is not enough access for the hammer head.

Claw

On specific types of hammer the claw makes up part of a hammer’s head and is positioned on the opposite side to the hammer face. A hammer’s claw typically features two V-shaped prongs, separated by a narrow opening.

Tips for Choosing the Right Hammer

There’s no such thing as a ‘one-size-fits-all’ hammer. From the head shape and weight to the handle length and material, each type of hammer is designed for a particular job, so it’s essential to always make sure you’ve chosen the right hammer for the task you’re taking on.

You wouldn’t get very far trying to drive in stakes using a tack hammer for example! That would be just as frustrating and fruitless as trying to use a sledgehammer for finer detail work, so the first thing to take into account when choosing a hammer type is the application.

What you’re trying to achieve – and the kinds of materials you’re working with – will influence which hammer you need to get the right result. A claw hammer for instance is ideal for carpentry applications but wouldn’t serve you so well for metalwork. For that, you’d be looking at using a ball peen hammer or a cross pein hammer. Likewise, if you’re working around highly flammable materials, you’d want to use a non-sparking hammer for safety.

Hammer size is also important. Small hammers may bend large nails out of shape, whereas large hammers may easily drive in nails but damage the bonding material in the process.

How to Properly Store Hammers

As with all tools, how long your hammers last depends on how well you care for them.

One of the best ways of preserving your tools is by storing them in a purpose-built tool solution, such as a roller cabinet or wheeled case – preferably with a shadow foam insert.

Alternatively, consider investing in a wall-mounted shadow foaming solution for your workshop. This will offer you both a handy storage solution and a way to keep your tools neatly organised and accessible.

Lastly, try and keep your tools away from moisture. If necessary, use a dehumidifier to capture any residual moisture in the air. Although most tools are made from high-grade anti-corrosive materials, this extra step will help to minimise the risk of any of your tools rusting.

Summary

Hammers are a versatile hand tool, helping you to perform a wide range of essential tasks, from metalwork, carpentry, and landscaping, to more intricate jobs such as shoe repairs and upholstering furniture. Choosing the correct hammer for the intended application will ensure that you complete each job safely, professionally, and to the highest possible standard.

If you’re confident in the type of hammer you need, take a look at the full selection of speciality hammers and mallets we offer at Red Box Tools. Or, for further advice, give our team a call on 02380 254285 or drop us an email.

If you found this guide helpful, don’t hesitate to browse our other tool guides, including spanners, wrenches, screwdrivers, and socket sets.